Overview

The Digital Diagnostics (DD) functions in MSA compliant transceivers are useful tools commonly used in Tele/Datacomm pluggable transceivers. Transceiver information and status are communicated over an I2 C interface using two pins or pads on the transceiver, dictated by transceiver multi-source agreements SFF-8472 and 8431. The Information fields show the technology and manufacturing data while the Optical Monitoring fields show the transceiver status while in use. Alarms and rate operation can be programmed in some parts to add additional functionality.

Features

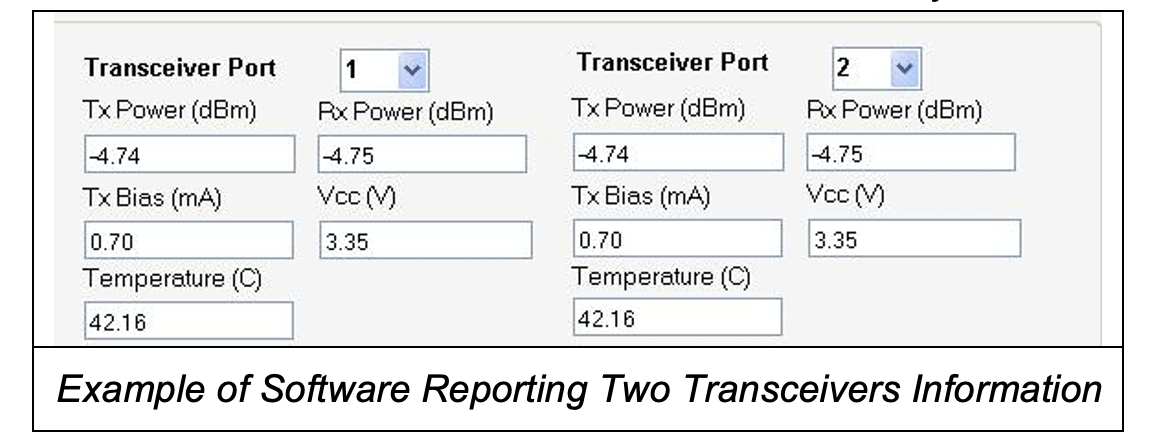

The DD interface has been widely used in network switches for years. By implementing DD, the transceivers become smart components while providing differentiation in both hardware (the capability itself) and the software to monitor it. Unfortunately, what was meant to be an open standard, has been used in pluggable transceivers to key them for specific switches protecting high resale prices from low-cost manufacturers in Asia and a ready aftermarket. The keying offers some value to the military/aerospace/industrial markets by preventing counterfeit component use in the field. However, more value can be derived from a customized implementation of software to enable accurate built-in-test and predictive failure analysis. COTSWORKS offers DD in our SFF, RJ, and RCP products which are unique for board-mounted configurations. Engineers can access memory locations found in our controller chip showing information such as wavelength, speed, and link length as well as Tx power, Rx power, electrical current draw, and temperature.

DD can be used to determine if a link fault is caused by the active or passive portion of the network. Because the Tx and Rx powers on both sides of the link can be measured, the insertion loss (IL) of the cable can be made. For example, if the first side of a duplex link has a Tx power of -5 dBm and is received at -9 dBm while the second side has a Tx power of -5 dBm but an Rx power of -20 dBm, the cable should be the first area to troubleshoot.

There are user-defined fields in the DD where COTSWORKS offers an option to store factory test data in the EEPROM in the Chip. This enables comparisons between operations at our factory and in the field. This is critical to doing predictive failure analysis: data is provided on power consumption and laser efficiency over temperature. Mil/Aero/Ind. operators who face much more difficult thermal management conditions can use DD to help increase MTBF and even service a transceiver before it fails.

Finally, and importantly, COTSWORKS’ RJ and RCP are calibrated to better accuracy than the 3 dB of the industry standard. That improved accuracy makes using DD on Multimode fiber much more valuable and viable. While not quite a power meter level, the RCP, for example, could be used for production test qualification in many environments.

Summary

For more information, including industry specifications for DD, the majority of transceiver form factors and a white paper on DD, contact sales@cotsworks.com or call 440.446.8800.